Revolutionize Quality Control: Our Lightning-Fast 2D & 3D Wire Bond Inspection Solution.

Are you tired of lengthy setup times and false call headaches?

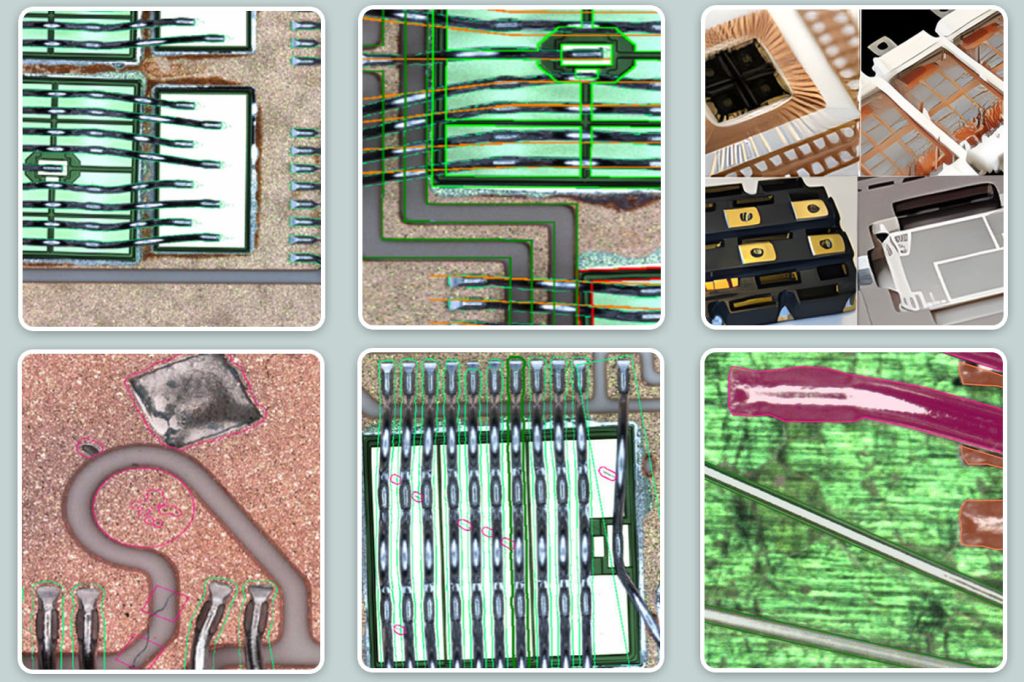

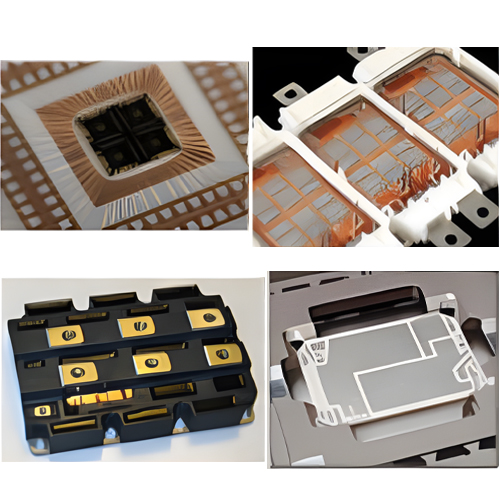

Our novel wire bond inspection approach transforms your quality control process. Whether you’re in the semiconductor industry or manufacturing electronic components, we’ve got you covered.

Why Choose Our Wire Bond Inspection Solution?

Lightning-Fast Setup: Say goodbye to hours or even days of fine-tuning. Our system gets you up and running within 30 minutes, so you can focus on what matters most—quality assurance.

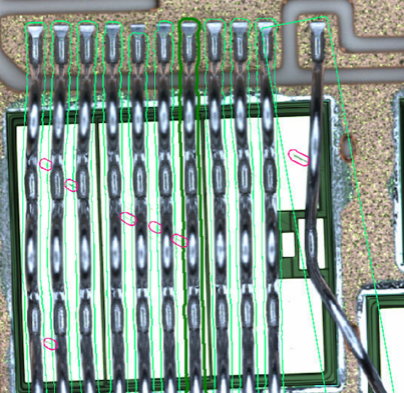

Ultra-Low False Call Rate: We pride ourselves on accuracy. With a false call rate

typically below 10%, you’ll catch defects without unnecessary alarms. Speedy Cycle Time: Need rapid inspections? No problem! Our system delivers lightning-quick results, often much less than 10 seconds per DBC/ IPM/ IGBT/ IHM/ SKM/… inspections.

Comprehensive Inspection:

All layers: Ceramic, copper, lead frames, wires, bonds, and dies—all in one go.

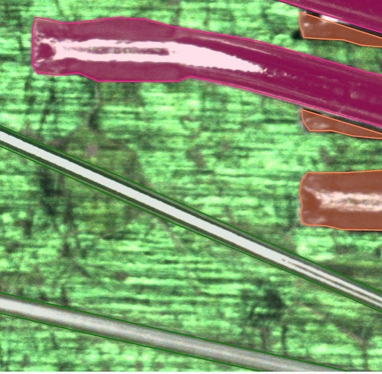

Wire Sizes: From smallest 18µm wires to large high-power ribbons.

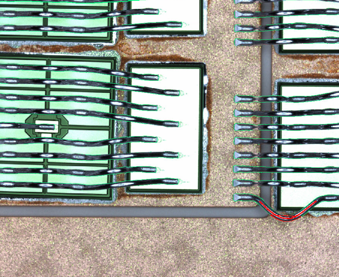

Substrate type: Inspect within package, module, DBC, or directly on substrates (leadframes, ceramic substrates, etc.).

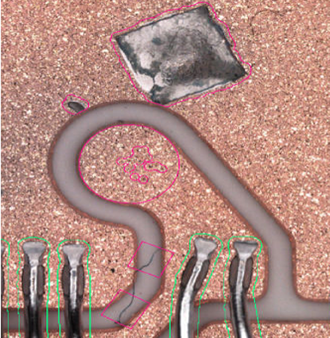

Lowest Escapee rate: Detect scratches on dies, solder paste splashes, … with our solution.

Multi-Die Capability: Seamlessly inspect wires across multiple dies without false alarms. Inspection at its finest!

Join industry leaders who trust our wire bond inspection system.

Boost productivity, reduce false calls review, and ensure repeatable quality for your customers.

Ready to revolutionize your inspection process?

Contact us today for a demo and

experience the future of quality control!

Application

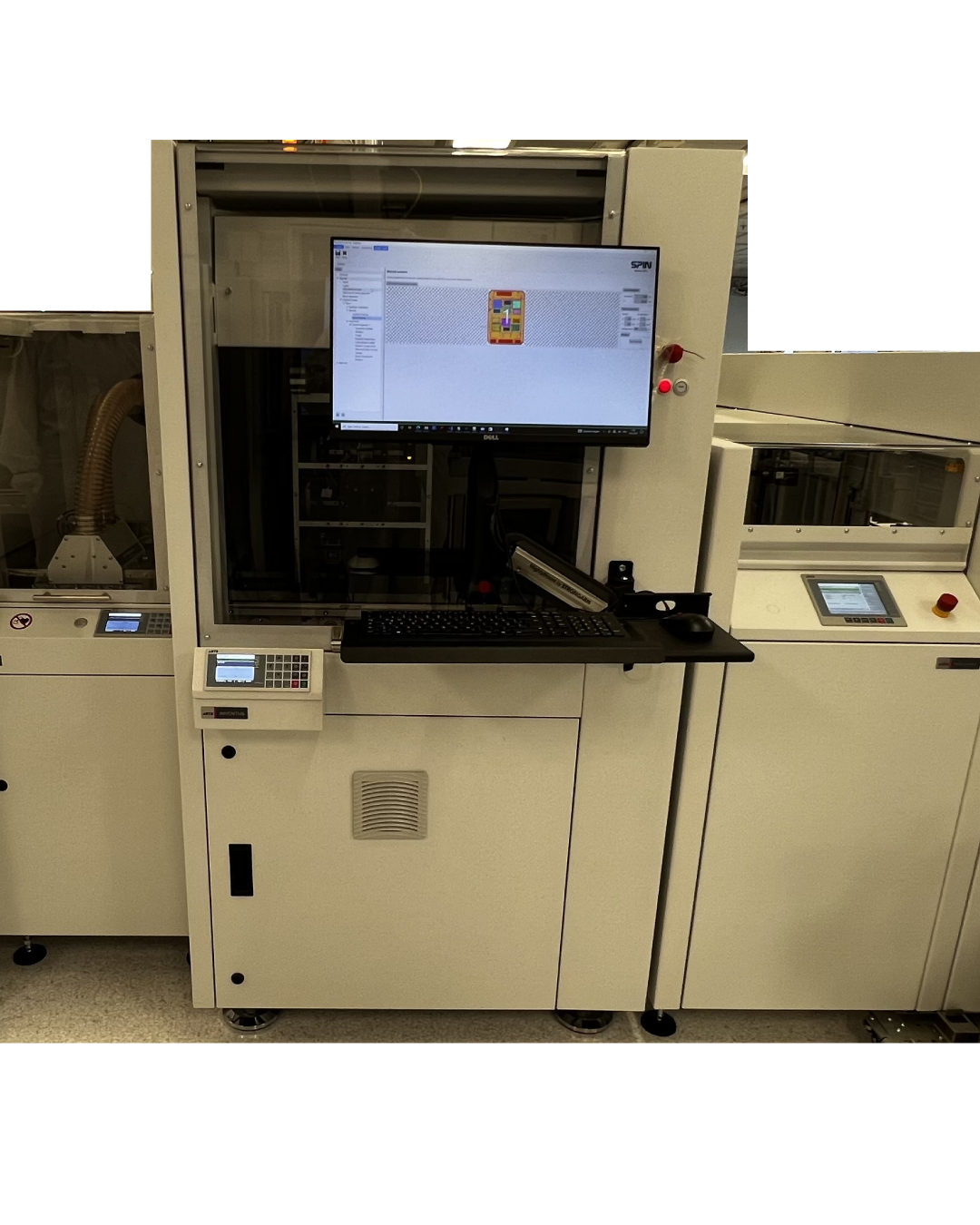

Cutting Edge Hardware

Capture every Detail without cycle time penalty

- Linear slides (up to 600mm/s)

- High Speed cameras (up to 30Fps)

Powered by the latest technology

- Nvidea hardware for AI

- 5µm resolution

- 20 Mpix camera 2000

- 1µm@6 sigma measurement accuracy

Seamless carrier transport

- Three conveyors for a quick mechanical exchange

- up to 320×320 carrier

Large focus distance

- Up to 40mm to accommodate modules and larger designs

CAD Base Inspection

Design to Reality using CAD inspection

- Confirmed inspection versus Golden sample guessing

- Measure produced result to intended design and correct

Faster to market time and Material/ Design evaluation

- Wire bond inspection setup in <30 minutes

- New complete product setup in ~ half day

- New Layout with same materials <1 hour

- No Fine Tuning!

Fastest Cycle Time for fastest investment return

- ~30 seconds for one carrier (e.g. 250x250mm)

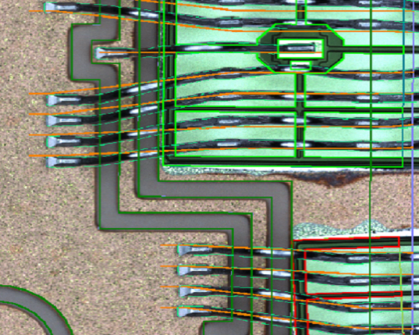

AI wire recognition – Box free wire recognition

- Yield increase due to no limitation to wire shift

- System automatically adapts to wire shifts

Enabling future products and technologies

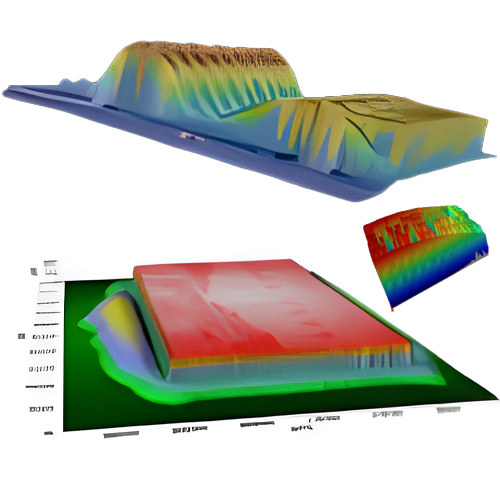

2D and 3D Inspection

3D inspections for comprehensive inspection

- BLT

- Loop height for expansion control

- Warpage test for flawless bonding

Module and lead frame complete Wire Bond inspection

- From housing onto DBC

- From DBC to DBC

Multiple Dies on one substrate

- Can inspect multiple dies on a substrates

- Even when dies are shifted differently, AOI will inspect the wires on top

- Confirm min. distance between Dies

Complete Inspection

Comprehensive inspection in one AOI

- Ceramic: Detects cracks, defects, or irregularities in ceramic

- Copper: Verifies copper defects, contaminations such as solder, and other damage.

- Wire: Inspects wire placement, integrity, spacing, and connection

- Leadframe: Verifies leadframe quality and detects damages

Highest repeatability for Data

- High Accuracy: delivers precise results, minimizing false call rates (usually single digit).

- Reliable Data: robust foundation for big data analysis and process optimization.

Inspection for wirebond with different criteria

- Gate wires

- Power wires

Standalone

Complete Solution

Inline

Customized Production Lines

Front & Backside Inspection Solutions

Clientele