BINDER SYSTEMS & PASTE VEHICLES

PII is the leading supplier of water-based tape casting technologies as well as polymer science solutions for the electronics, medical, and energy fields and beyond.We are experts in tape casting, formulation & development of green tapes, process & sintering optimization as well as the general use of organic polymers. We also specialize in multi layer device development, product prototyping and scale up procedures.

General Specification

Laminationlow temperature low pressure lamination

Materialsferrites, Al2O3, AlN, ZrO, Metals, battery, PZT, Piezo, NiZn, ceramic Fuse, Yttrium, Barium Titanate

Typespowder pressing, doctor blade casting, slot die, rolling, wet in wet processing

Cast Thickness1µm~1.000µm

Products

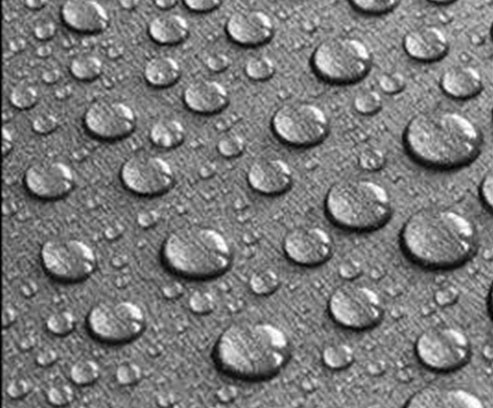

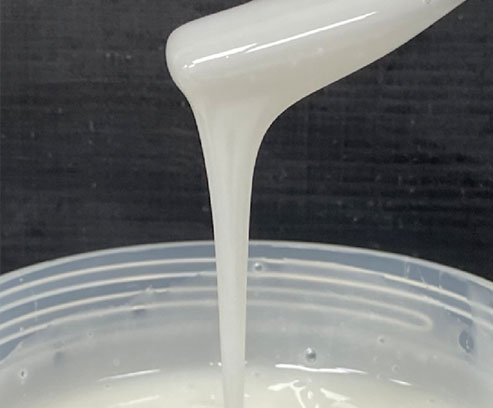

Binder waterbased

WB4101

Most popular water based binder with basic defoamer, wetting agents and other additives. In general will outperform popular solvent based systems. Binder also acts as ceramic dispersant and therefore typically 25-50% of the total binder should be included in the grinding stage. WB4101 is 35% solids (28% polymer and 7% plasticizer). For more specific tape casting guidelines PII can be contacted for example formulas for certain ceramic types and there are several other resources such as the presentation called “Tape Formulation”, the demonstration kit and custom formulation services are also available.

WB40B-67

Similar to above (same polymer type) but with none of the plasticizer used in the WB4101.It is useful for making stiffer and harder tapes. Binder solids are 27% (27% polymer and 0% plasticizer).

Additives for casting

Defoamer

Plasticizer

Steel Belt release agents

Thicker casting additives

Dispersing Agents

Wetting Agents

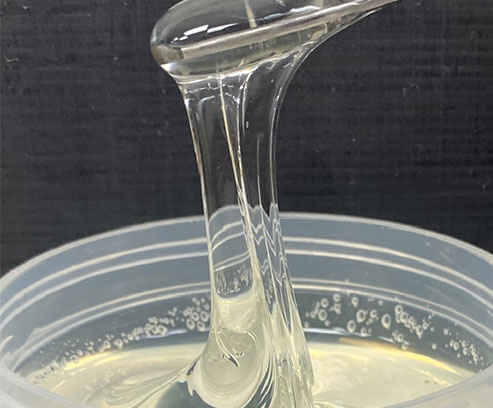

Paste Additives/ Print Vehicles

Thixotropic additive

Dispersants

Thinners

EV110H low temperature Epoxy vehicle (down to 120C)

VS36H Electrode printing vehicle,

EV120H one part heat cure epoxy vehicle for creation of printing pastes. Higher cure temperature (180C) and long shelf life.