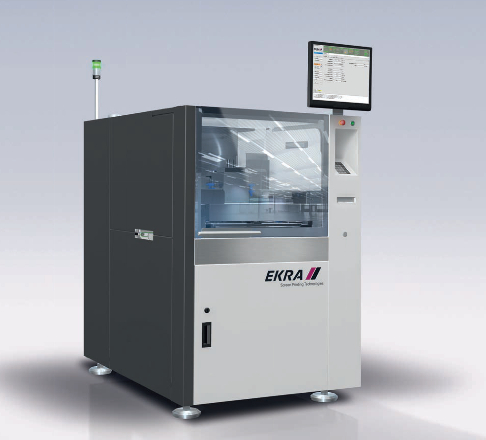

Screen Printing Machine

EKRA is best known for their SMT Stencil Printers. For several decades, they have also been producing print systems for various industry segments outside of SMT-applications.

This includes

- Printing of ultra-fine structures,

- 3D shapes

- Functional coatings on different materials including glass, ceramics, LTCC/HTCC, foils, metal tubes, wafers and textiles.

General Specification

Material size1x1mm up to1.600×2.000mm

Cycle timedown to 0.8 seconds/ part

Structuresdown to 18µm

Alignment Accuracydown to +/-3µm

Features & Options

- Automatic looking setup of all print parameters

- Alignment accuracy +/-10 μm @ 6 Sigma

- Dedicated unique print nest and table solutions

- Automatic loading

- Automatic screen exchange

- Curing, IR or UV unit

- 3D measuring system,

- 100% inline inspection

- Precise adjustment of the snap lock

- Different types of levy

- Motorized squeegee head

- Stencil cleaning system iROCS

- Dispensing systems

Machines

Manual alignment

E2

- Since 2014

- Print frame with 4 pillar guides for highest precision and repeatability

- Printing area up to 300 x 300 mm (12 inch)

- Patented optical positioning system EVATM – EKRA Vision

- Alignment System using edge recognition, fiducial recognition or

- 2 independent pneumatic driven print heads with precision proportional valves with closed-loop control

- Closed loop for printer alignment Automatic loading/unloading possible Alignment repeatability ± 5 μm @ 3 Sigma

Technical Data

| Maschinen Dimensionen / Machine dimensions | E2 | E2XL |

|---|---|---|

| Länge x Breite x Höhe / Length x width x heightGewicht / Weight | 1450 x 1150 x 1400 mmca / approx. 550 kg | 1700 x 1300 x 1400 mmca /approx.650 kg |

| Installation requirements | ||

| Elektrischer Anschluss / Power requirementsLeistungsaufnahme / Power consumptionAbsicherung / Fuse protectionPneumatischer Anschluss / Air supplyLuftverbrauch / Air consumption | 230 V AC;50 / 60 Hz; 1L+N+PE1,2 kW16 A6 – 10 bar1,5 Nl/min | 230 V AC;50 / 60 Hz; 1L+N+PE1,2 kW16 A6 – 10 bar1,5 Nl/min |

| Rakel / Print parameters | ||

| Rakelgeschwindigkeit / Print speedRakeldruck / Print pressureRakelmode / Print mode | 10 – 170 mm/s10 – 250 NDruck – Druck / Print – PrintDruck – Fluten / Print – FloodFluten – Druck / Flood – PrintWechseldruck / Alternating print | 10 – 170 mm/s10 – 250 NDruck – Druck / Print – PrintDruck – Fluten / Print – FloodFluten – Druck / Flood – PrintWechseldruck / Alternating print |

| Druckgut / Print material (X/Y) | ||

| Rahmengröße min. / Frame size min.Rahmengröße max. / Frame size max.Druckformat max. / Print format max.Druckgutstärke / Print material thickness | 300 x 300 mm620 x 740 mm370 x 450 mm0,8 – 6,0 mm | 300 x 300 mm620 x 740 mm370 x 450 mm0,8 – 6,0 mm |

| Prozess / Machine capability | ||

| Ausrichtgenauigkeit / Alignment accuracy | ± 10 μm | ± 10 μm |

| Aufstellbedingungen / Installation requirments | ||

| Temperatur / TemperatureFeuchtigkeit / Humidity | 25°C +/- 10°C50%+/- 20% (nicht kond.) /(non cond.) | 25°C +/- 10°C50%+/- 20% (nicht kond.) /(non cond.) |

M2H

- The M2H semi-automatic screen printer has been designed for printing of ceramic hybrids in applications with small to medium size production volumes, R&D and laboratory as well as proto-typing purposes.

- But also a large variety of other flexible and rigid substrates up to a size of 180 x 160 mm can be processed on the M2H. The substrates can be placed on to different types of print nests mounted on the horizontally moving table. For a convenient substrate alignment, the printer can optionally be equipped with the manual optical positioning system MOPS. The substrate is then manually aligned using high resolution cameras for reliable recognition of fiducials or other layout features.

Technical Data

| Machine dimensions | |

|---|---|

| Length x width x height | 1150 x 1000 x 1340 mm |

| Weight | 440 kg |

| Installation requirements | |

| Power requirements | 230 V AC ; 50 / 60 Hz, 1L+N+PE |

| Fuse protection | 2 kW |

| Air supply | 6-10 bar |

| Air consumption | 40 Nl/min |

| Print parameters | |

| Print speed | 10 – 200 mm/s |

| Print pressure | 10 – 200 N |

| Print mode | Print – PrintPrint – FloodFlood – PrintAlternating print |

| Print material (X/Y) | |

| Frame size min. | 203 x 152 mm |

| Frame size max. | 305 x 305 mm |

| Print format max. | 180 x 160 mm |

| Print material thickness | max. 30 mm |

| Positioning | manual |

| Print material (X/Y) | |

| Alignment accuracy | ± 7,5 μm |

| Installation requirements | |

| Temperature | 25°C +/- 10°C |

| Humidity | 50% +/- 20% (nicht kond.) / (non cond.) |

Automatic alignment

XH-STS

- The XH STS stencil and screen printing system was specially developed for printing substrates in thick film applications. The flexible system can be used in a wide number of areas within the hybrid, SMT and solar fields. The automatic offljne prjnt system is particularly suitable for thickfilm printing of small to mid-range production volumes which require highest precision and short tooling times.

- A porous stone is used as the standard print nest which means that all flat substrates can be positioned on the pant table, independent of their form, Even very thin materials such as wafers,solar cells. tapes or foils can be accurately printed. An additional advantage is that the incurred costs for specific print nests can be avoided Customer-specific pant nests are available upon request.

Automatic inline

Technical Data

| Machine dimensions | |

|---|---|

| Length x width x height | 1498 x 1460 x 1552 mm |

| Weight | 930 kg |

| Installation requirements | |

| Power requirements | 400V AC; 50 / 60 Hz 3L+N+PE |

| Power consumption | 2,3 kW |

| Air supply | 6-10 bar |

| Air consumption | 2 Nl/min |

| Print parameters | |

| Print speed | 10 – 300 mm/s |

| Print pressure | 10 – 250 N |

| Print mode | Print – PrintPrint – FloodFlood – PrintAlternating print |

| Print material (X/Y) | |

| Frame size min. | Up to 450 x 450 mm with adapter frame |

| Frame size max. | 584 x 740 mm with screen support rail |

| Print format max. | 300 x 300 mm |

| Substrate thickness | 0,1 – 20 mm |

| Positioning | Edge recognition, fiducial recognition and synthetic fiducials |

| Machine capability | |

| / Alignment repeatability | ± 10 μm @ 6 Sigma |

| Installation requirements | |

| Temperature | 25°C +/- 10°C |

| Humidity | 50% +/- 20% (nicht kond.) / (non cond.) |

XW-STS

- The flexible machining cell is designed for front or back side printing (bumping or wafer backside coating) on round wafers. The system consists of two main modules, a loading unit and a printing system. The loading unit in turn consists of three components a magazine unloading system, a robot unit and a pre-align station.

- The magazine unloading system is equipped with two magazine positions from where the wafers are fed to the machine. The 3-axis robot unit with vacuum end effector ensures a stress-free wafer transport. Using a flexible pick-up, different end effectors can be used even for very thin or curved wafers.

Technical Data

| Machine dimensions | |

|---|---|

| Length x width x height, Weight | 2550 x 1460 x 1552 mm, 1950 kg |

| Installation requirements | |

| Power requirements | 400V AC; 50 / 60 Hz 3L+N+PE |

| Power consumption | 2,3 kW |

| Air supply | 6-10 bar |

| Air consumption | 2 Nl/min |

| Print parameters | |

| Print speed, Print pressure | 10 – 300 mm/s, 10 – 250 N |

| Print material (X/Y) | |

| Frame size min. | Up to 450 x 450 mm with adapter frame |

| Frame size max. | 584 x 740 mm with screen support rail |

| Print format max. | 300 x 300 mm |

| Print material thickness | 0,1 – 20 mm |

| Positioning | Edge recognition, fiducial recognition and synthetic fiducials |

| Machine capability | |

| Alignment repeatability | ± 10 μm @ 6 Sigma |

| Installation requirements | |

| Temperature | 25°C +/- 10°C |

| Humidity | 50% +/- 20% (non cond.) |

Automatic inline

XH2

- The XH2 screen and stencil print system has been specially developed for printing hybrids, with a particular emphasis on combining highest precision with maximum flexibility.

- This inline print system utilizes the patented EVATM – EKRA Vision Alignment System. The EVATM system is an optical positioning system with a free-moving camera. Both the camera axis and the screen adjustment assembly have integrated high precision measuring systems which together ensure a repeatability of ± 12,5μm@ 6 Sigma.

Technical Data

| Machine dimensions | |

|---|---|

| Length x width x height | 1000 x 1440 x 1550 mm |

| Weight | 880 kg |

| Installation requirements | |

| Power requirements | 400 V AC; 50 / 60 Hz, 1L + N + PE |

| Power consumption | 2,3 kW |

| Air supply | 6-10 bar |

| Air consumption | 2,5 Nl/min |

| Print parameters | |

| Print speed | 10 – 300 mm/s |

| Print pressure | 10 – 250 N |

| Print mode | Print -PrintPrint – FloodFlood – PrintAlternating print |

| Print material (X/Y) | |

| Frame size min. | Up to 450 x 450 mm with adapter frame |

| Frame size max. | 584 x 740 mm with screen support rail |

| Print format min. | 2 Zoll x 2 Zoll |

| Print format max. | 250 x 250 mm |

| Print material thickness | 0.1 – 1.5 mm |

| Positioning | Edge recognition, fiducial recognition, synthetic fiducials |

| Machine capability | |

| Alignment repeatability | ± 12,5 μm @ 6 Sigma |

| Cycle time | 3,5 s + print time |

| Installation requirements | |

| Temperature | 25°C +/- 10°C |

| Humidity | 50% +/- 20% (non cond.) |

XH1

- Fastest cycle times and High Precision are the key features of the fully automated XH1 screen printer. The XH1 is the high-end solution for printing of ceramic substrates.

- Its design is unique on the market and is based on excellent experience over many decades in the hybrid market.

- The overall throughput of the system is in the range of 3,2 s including printing and is not only the result of a short handling time but includes as well the fully automated screen alignment. The extremely easy product changeover can be reduced to about 1 min and can be performed as well by low level instructed operators.

Technical Data

Print parameters

| Machine dimensions | |

|---|---|

| Length x width x height | 1000 x 1440 x 1550 mm |

| Weight | 840 kg |

| Installation requirements | |

| Power requirements | 4230 V AC; 50 / 60 Hz, 1L+N+PE |

| Power consumption | 2,3 kW |

| Air supply | 6-10 bar |

| Print speed | 10 – 300 mm/s |

| Print pressure | 10 – 250 N |

| Print mode | Print -PrintPrint – FloodFlood – PrintAlternating print |

| Print material (X/Y) | |

| Frame size min. | 350 x 350 mm |

| Frame size max. | 450 x 450 mm |

| Print format min. | 4 Zoll x 4 Zoll |

| Print format max. | 6 Zoll x 7 Zoll |

| Print material thickness | 0,1- 1,5mm |

| Positioning | Edge recognition |

| Machine capability | |

| Alignment repeatability | ± 12,5 μm @ 6 Sigma |

| Cycle time | 3,2 s incl. print |

XH3

- The automatic screen printing system XH3 is perfectly equipped for thick-film applications. It comes with a transport system, which has been specifically designed for the processing of abrasive materials (ceramics), Furthermore, the printer is equipped with a product specific vacuum print nest and a customized print head for screen printing applications.

- A camera allows the identification of structures of the screen. In the ceramic division, the printing system can be used for substrates in a size of between 4 and 7 inches (thickness 0.63 mm).Optionally, small and thin substrates up to 2×2 inches (thickness 0.35 mm) are easy to process. With specific adapter bars the XH3 can also be used with casted profile frames, in addition to conventional frame profiles.

Technical Data

Print material (X/Y)Installation requirements

| Machine dimensions | |

|---|---|

| Length x width x height | 1140 x 1700 x 1488 mm |

| Weight | ca. 1000 kg |

| Installation requirements | |

| Power requirements | 400 V AC, (480 V AC); 50 / 60 Hz 3L+N+PE |

| Power consumption | 2 kW |

| Fuse protection | 16 A |

| Air supply | 5 – 6 bar |

| Air consumption | 1,5 Nl / min |

| Frame size min. | 350 x 350 mm |

| Frame size max. | 740 x 740 mm |

| Print format min. | Ceramic: 4 x 4 inches’, 2 x 2 inches’Others: 80 x 50 mm |

| Print format max. | Ceramic: 7 x 7 inches others: 508 x 508 mm2 |

| Substrate thickness | 0,63 bis 6 mmoptional 0,35 mm3 |

| Positioning | Fiducial recognition |

| Machine capability | |

| Repeat accuracy | ± 12.5 μm @ 6 Sigma |

| Frame size max. | 450 x 450 mm |

| Cycle time | 12 s + print time(optional 5 s + print time ) |

| Temperature | 25°C +/- 10°C |

| Humidity | 50% +/- 20%(non cond.) |

XL3

- Sizes up to: 1,5m

- Substrate weight up to 10 kg

- Alignment, optical edge and structure, mechanical mid centering alignment

- Special guidance free transport- and automation units

- Movable camera, only XL3, as an option

Technical Data

Print material (X/Y)Installation requirements

| Machine dimensions | |

|---|---|

| Screen size max. | 1800 x 1200mm |

| Print size max. | 1200 x 800mm |

| Thickness max. | 10mm |

| Installation requirements | |

| Machine capability | |

Customized Production Lines