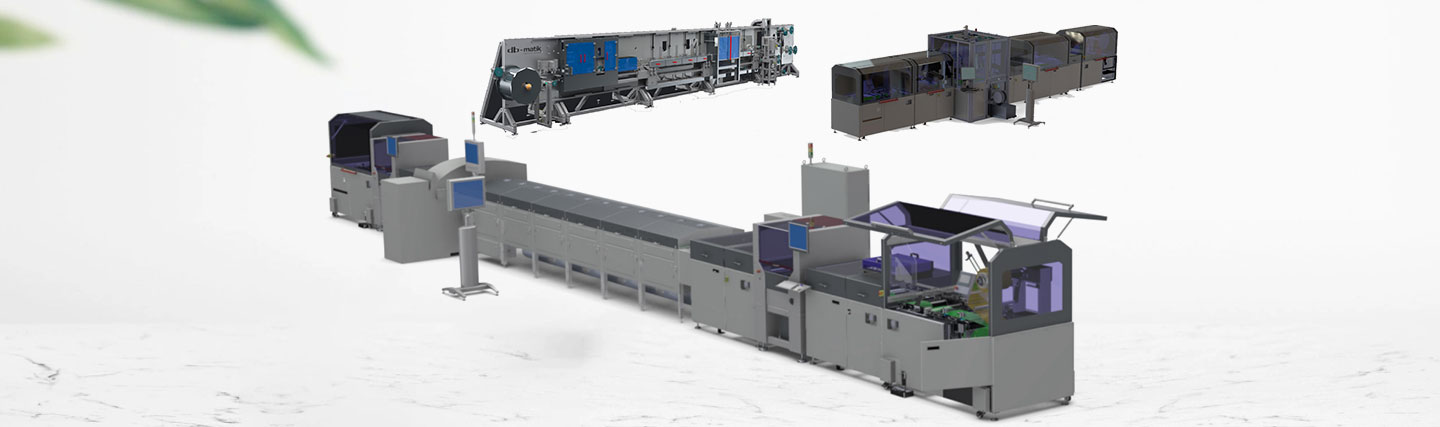

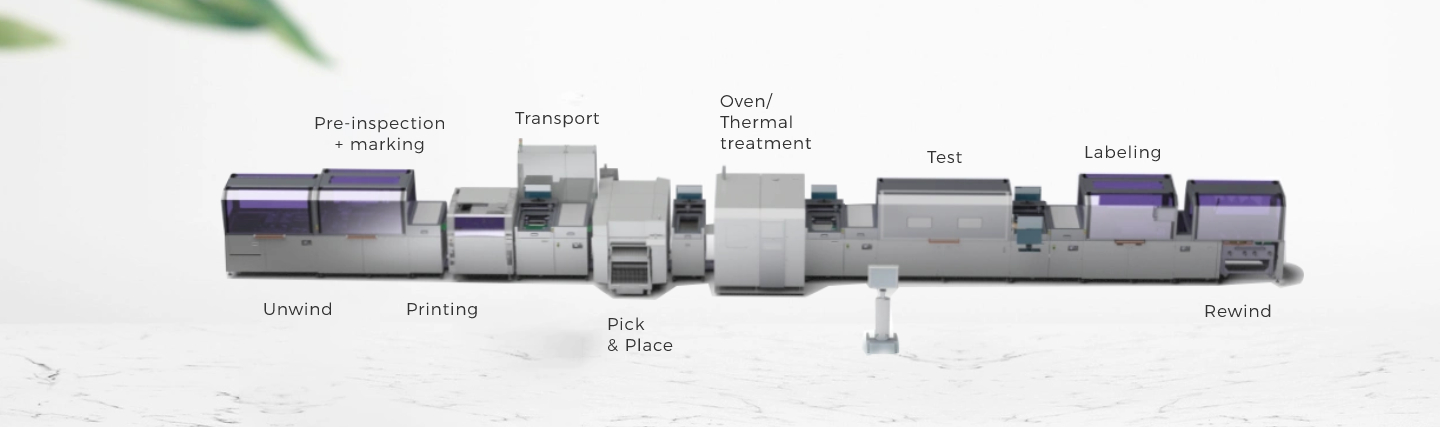

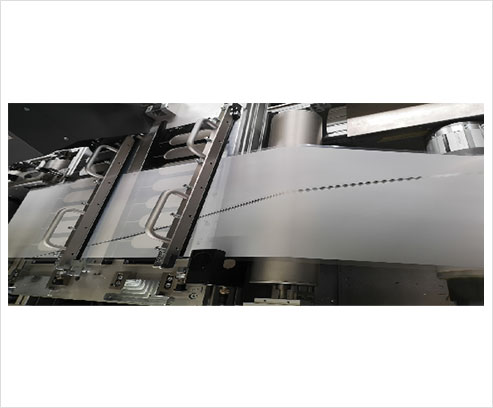

Reel to Reel / Roll to Roll

Automation for flexible substrate production by taking the production process from a sheet by sheet processing to a R2R production solution. The core of our experience is in processes that require screen and stencil print to make conductors on a flexible material. Processes that can also be integrated into this solution are heat treatment, inspection, marking, testing and pick and place modules.

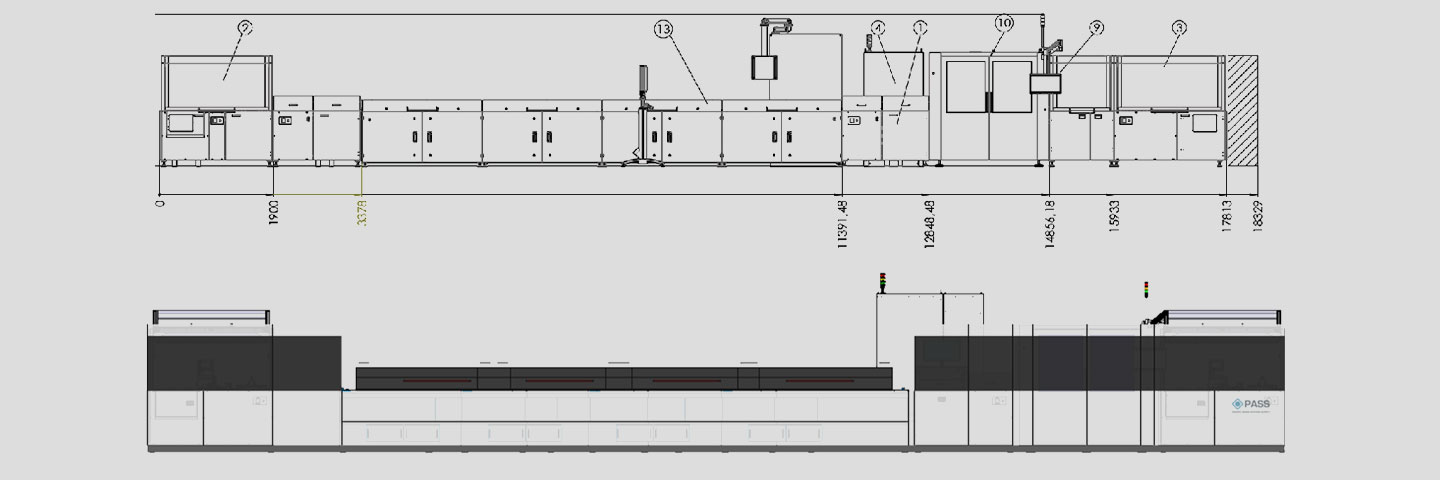

General Specification

Material sizeup to 600mm wide

Cycle timedown to 2.7 seconds for 350x350mm process area

Structuresdown to 30µm

Thicknessdown to 1µm

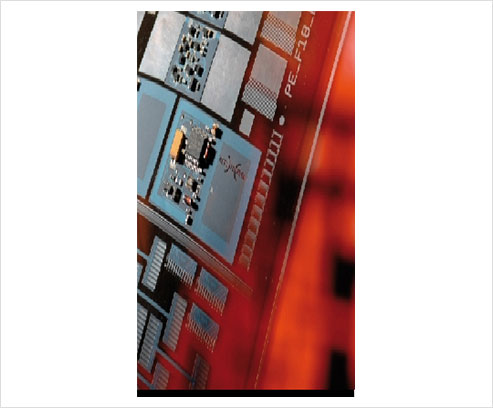

Applications

Consumer

Aerospace

Automotive

Medical

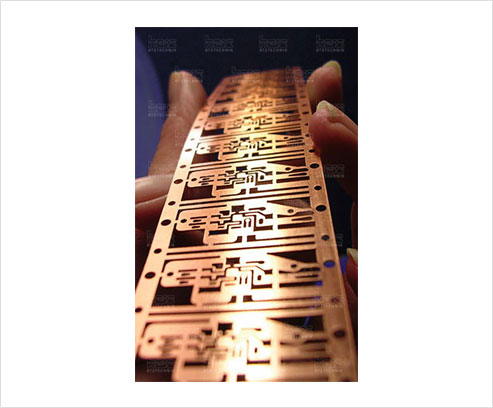

Copper

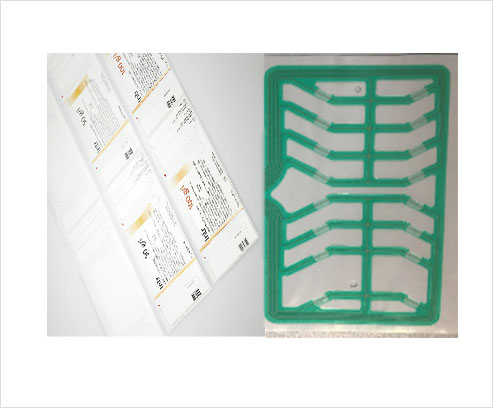

Paper

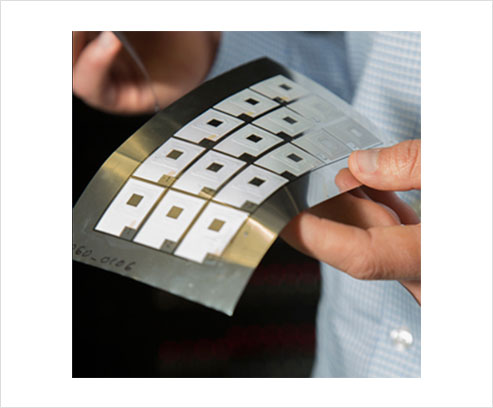

PI/PET

Composite

Customized Screen printing solutions

UNWIND

- Up to 500mm width, adjustable

- Vacuum buffer,

- No touch on the surfaces of your material.

- Down to 15μm material thickness

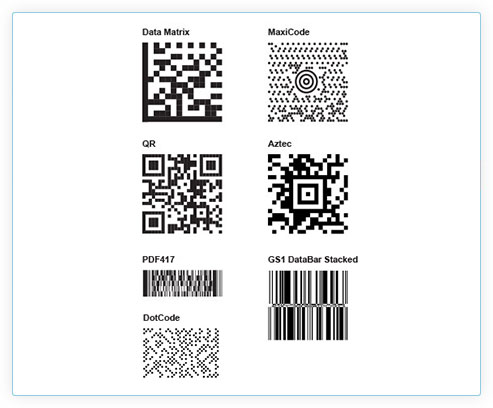

LABELING

- Marking (punch, ink, scrape)

- Vacuum buffer,

- Barcodes, data matrix codes

- Graphical user interface with easy handling.

SCREEN PRINT

- Down to 30μm

- Up to 1.100×1.100mm frames

- Automatic dispensing

- Flood inspection

- Up to 600mm/sec print speed

- Min. print gap

- Cycle time down to 2.8 seconds

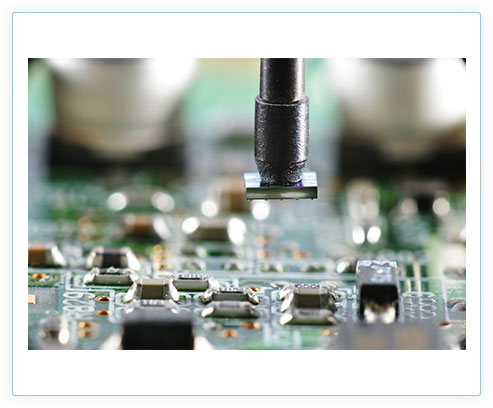

PICK & PLACE

- SMD parts placement modules

- New records in speed

- Floorspace performance

- Different suppliers can be intergated – Flood inspection.

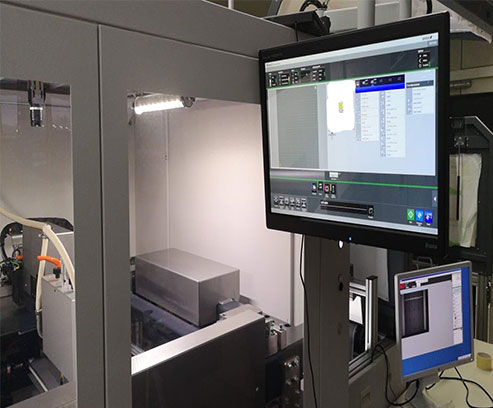

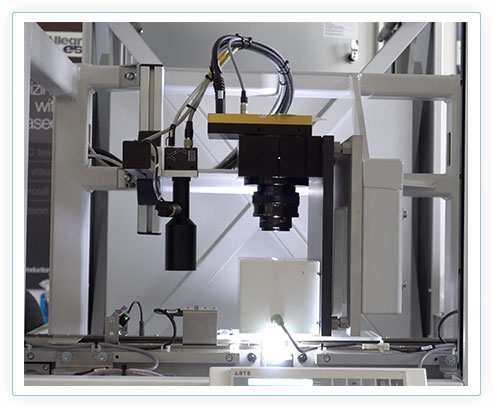

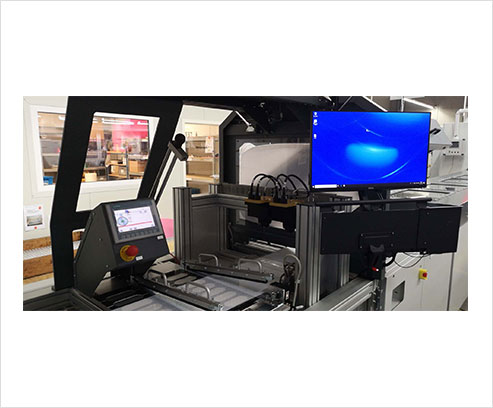

INSPECTION/ AOI

- Incoming material inspection

- Print inspection against CAD

- metrology 2D/ 3D

- Good/ Bad sorting/ marking

- Online Yield monitoring

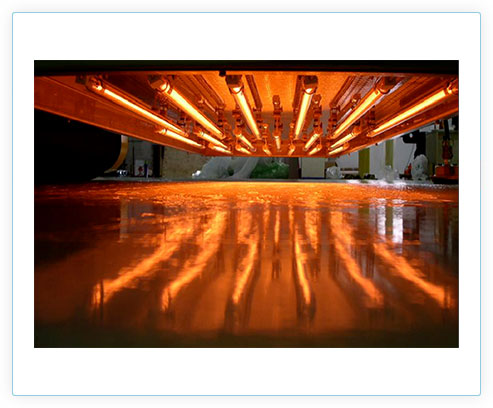

THERMAL TREATMENT

- Convection

- IR

- UV

- Variable length & temperature

SPECIAL

- Cutting sheets or stripes.

- Cleaning

- Camera Systems for positioning.

- Cleaning

REWIND

- Rewind the material or packaging sheets.

- Quick change substrate trolleys for easy material change and handling.

- Splicing tools.

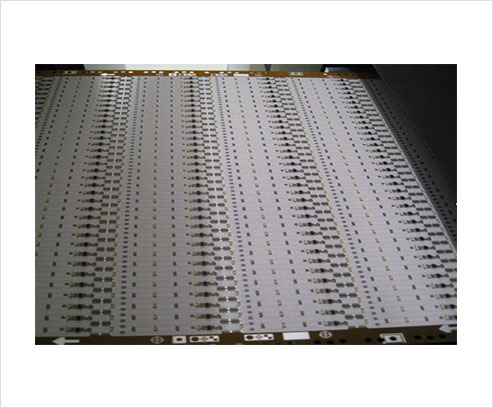

MLCC Print Lines

Unwind/ Loading

Incoming quality check

Screen Print

- Frame Size: up to 1100x1100mm

- Print Speed: up to 600mm/ sec

- Max. print size: up to 500x500mm

- Automatic feature for multilayer print Automatic paste dispensing

Auto Setup functionality

- Bar code and DATA matrix recognition

- Examination and of medium, material and tool

- Automatic startup with correct barcodes:

- Screen

- Paste

- MLCC roll

- Squeegeev

- Operator

Horizontal Configuration Oven

- Customer defined length

- Convetion heating

- IR heating

- LEL certification Option

- Multizone/ Modular

- Pressure Operated (clean)

- Sensor Opening

100% inline Inspection

- Level inspection (e.g. >75% defect/ stop)

- Labeling, Inking, …

- Offset check

- Print Area check

- Shrinkage check