Tape Casting Machine

Tape casting is a casting process used to manufacture thin layers from a slurry cast onto a flexible base. KMS produces tape casting solutions for R&D to industrial production of applications such as ceramic tape casting (e.g. LTCC/HTCC/MLCC foils), solid oxide fuel cell (SOFC) ceramic, electrolyte and electrode layer casting of batteries, adhesive layer coating on metal foil, …. Our speciality is the complete integrated solutions and accompanying our customers from their initial development to scaling them up to large production.

General Specification

Material sizeup to 1.000mm wide

Castingsingle layer, multilayer, backside, front side, intermittent, slot die, doctor blade

Typesteel belt, PET, copper, aluminum

Thikness 1µm to 1.200µm

Machines

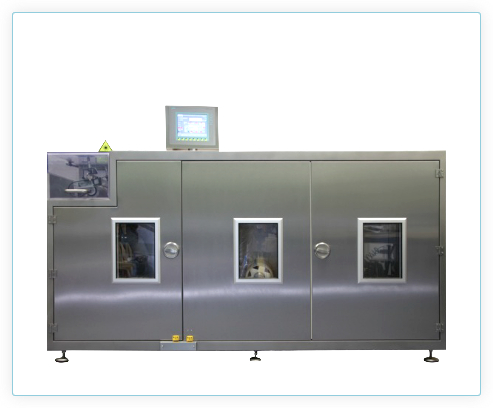

Compact

KC300

- Compact, Continuous system for casting ceramic tape on coated PET-film.

- One of the smallest and most accurate machines on the market

- Doctor Blade or / and Slot Die

- Easy to operate, low maintenance

- Serial production or lab operation

cast thickness

The KC-series casts ceramic tape to a thikness from 3-400 microns(dry) depending on the slurry (solid content, rheology,etc), Thinner casting(1um) has been done with special formulations.

cast Method

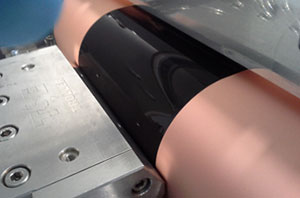

Doctor-Blade Technology, ” Blade over Roll” type casting method. Precision ground carbide casting blade, Thikness variation of the PET-film are automatically eliminated. The model KC300 is prepared to accept a slot die ( AAA-grade), allowing both continuous and intermittent coating e.g for lithium-ion batteries.

Dimensions

approx. 110cm high (inch.monitor / touch screen approx. 160cm high). Length: KC300-7 approx. 265cm

Weight

approx.500-600kg, depending on configuration.

construction

Stainless steel welded frame, stainless steel enclosure. easy to clean up slurry spills.

air flow

Two fans draw air through a HEPA filter. One fan provides intake air while the other is used to exhaust air. Each fan is independently controlled so the drying chamber can operate at a positive or negative pressure. Negative pressure is used in a clean room and positive pressure is used if the machine is not in a clean room.

tape cleaning

Each side of the carrier film is rolled over a apecial “tacky” roller to remove debris before enterning the casting chamber.

drying

Five/seven individually controlled sealed heating plates. Temperature settings and tolerances are set via the touch screen. The intake air has a heater as well (counter flow drying)..

KC700

Cast method

Doctor bladeslot die

Drying

fixed 7mConvectionheating plates

Transport

Mylar/ PETother thin materials (Aluminium, Copper, …)

Casting

100mm ~250mm wide5µm to 400µm

Options

Thickness Sensor

Automatic Slurry feed

R&D/ Lab coating machines

TC 10,20

Cast method

Doctor bladeslot die

Drying

1.000~3000mm lengthConvectionair dryingheating plates

Transport

Mylar/ PETother thin materials (Aluminium, Copper, …)

Casting

100mm ~300mm wide5µm to 500µm

Options

Thickness Sensor

Automatic Slurry feed

LC10,20

Cast method

Doctor bladeslot die

Drying

Convectionheating platesIR top heating

Transport

Mylar/ PETother thin materials (Aluminium, Copper, …)

Casting

100mm ~400mm wide3µm to 600µm

Options

Cutting Thickness Sensortension monitor exhaust monitor

Slurry monitor

PC 20

Cast method

Doctor bladeslot dieCo-CastingMultiple head Casting

Drying

Convectionheating platesIR top heating

Transport

Mylar/ PETother thin materials (Aluminium, Copper, …)Steel Belt

Casting

100mm ~300mm wide5µm to 1.000µm

Options

Cutting Thickness Sensortension monitor exhaust monitor

Slurry monitor…

Production machines

SOFC Caster

Cast method

Doctor bladeslot dieCo-Casting Multiple head Casting

Drying

Convection heating plates IR top heating

Transport

Mylar/ PETother thin materials (Aluminium, Copper, …)Steel Belt

Casting

100mm ~800mm wide5µm to 800µm

Options

Cutting Thickness Sensortension monitor exhaust monitor Slurry monitor…

CM 50 Production casters

Cast method

Doctor bladeslot die

Multiple head Casting

Drying

Convection heating plates

IR top heatingUV

Transport

Mylar/ PETother thin materials (Aluminium, Copper, …)Steel Belt

Casting

100mm ~1.000mm wide1µm to 1.200µm

Options

Cutting Thickness Sensortension monitor exhaust monitor

Slurry monitor